The right batteries can deliver longer life, lower maintenance, and reduce costs – and help ensure you have power when you need it. But batteries aren’t made equal, and there is no one-size-fits-all technology. So how do you find out which batteries are best for your renewable energy/off-grid application?

In this article for Solar Power World, Crown Battery’s John Connell, reveals what to look for in battery when it comes to off-grid and mobile living.

Understand Different Battery Types

The first step is to select the right type:

- Lead-acid batteries are made for specific applications, and some aren’t a good fit for renewable energy (RE) systems.

- Automotive and commercial starter batteries deliver short bursts of power and stay at full charge most of the time, making them unsuited for such applications. Uninterruptible power supply (UPS) batteries are designed to provide backup electricity during power outages but will not tolerate continuous discharge and charge cycles.

- Deep-cycle batteries deliver electricity for a long time, even multiple days, because they’re designed for constant discharge and charge cycles.

- Flooded batteries are the most commonly used batteries in renewable energy (RE) and grid-backup systems, because they’re affordable, easy to maintain, long-lasting and reliable.

Materials And Manufacturing Matter

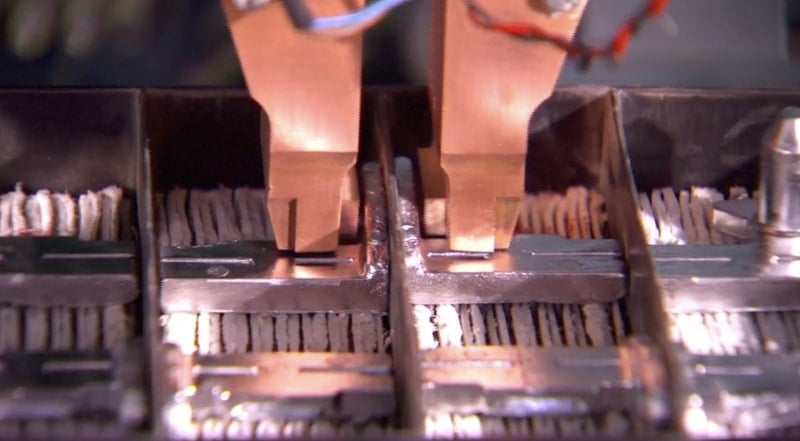

Metal grids that hold lead paste make energy storage possible. Thicker, heavier plates withstand corrosion longer and hold more lead for chemical reactions, so they increase battery life.Once grids are pasted, they’re cured (dried in specialized “curing ovens” at a particular temperature and humidity) to bond active lead materials to the grid for better performance and longer life.

Look for batteries built with plates prepared in curing ovens, which optimize important variables such as temperature and humidity at every stage of the curing cycle to ensure all plates deliver optimal capacity and service life.

Battery MAnufacturing Process

Quality control should be built into all stages of production to improve product quality and consistency. In more advanced plants, this includes machine testing for short circuits, along with computerized welding and heat sealing. Some battery companies even use vision systems (image capturing and advanced software that automatically inspect parts) to spot defects humans can miss.

When you know what to look for — and what to avoid — in a renewable energy battery, it’s much easier to find the best model for your needs. To compare manufacturing techniques and materials and get a better idea of which batteries will perform better and last longer, visit your RE battery manufacturer’s website or call the manufacturer or your distributor.

Read the full in depth article here.

Click here to learn more about which batteries are best for your off–grid or mobile living application.